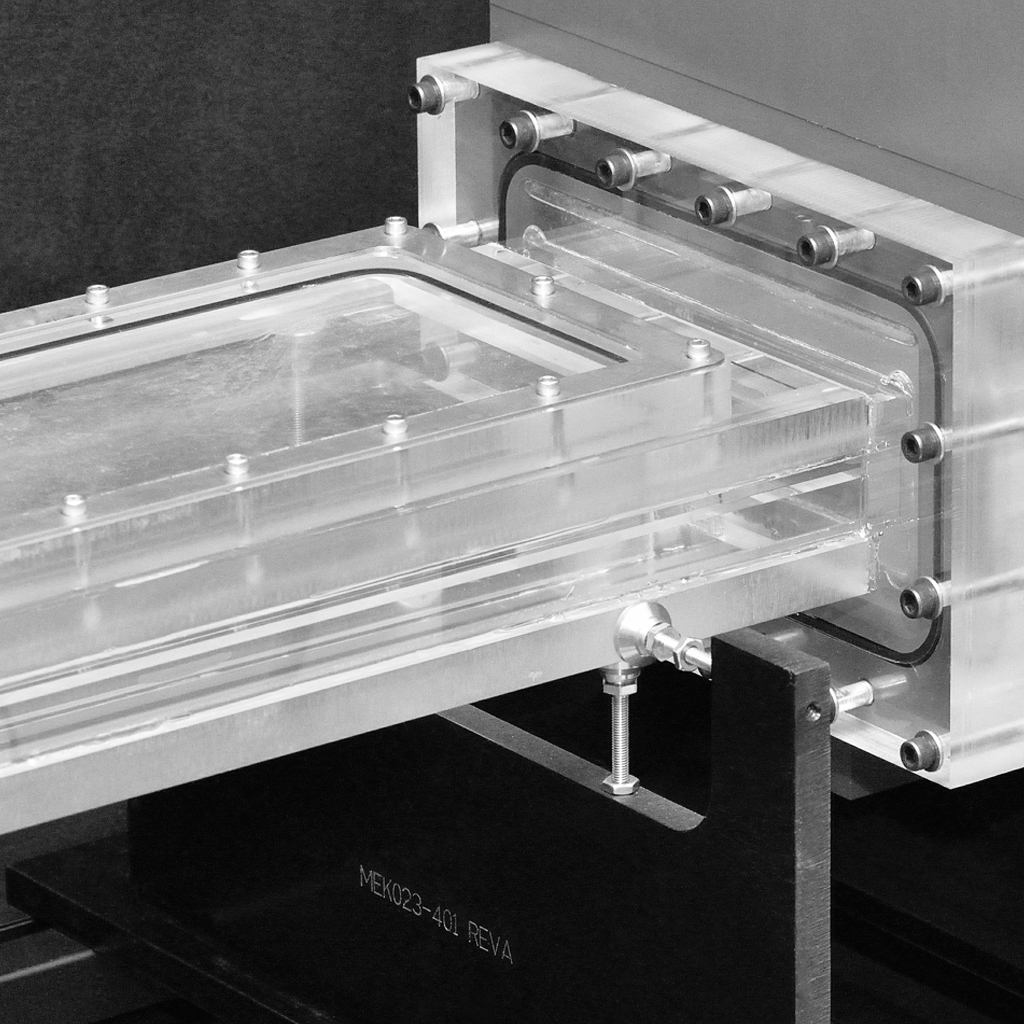

Test bench for measuring and validation electro-broadcast probes with a laser Doppler

Sector

Fluid mechanics

Societal benefits

An important part of the energy losses or yield reductions of systems using fluid circulation is related to the fluid’s friction with parts involved in the system. The development of a sensor able to locally provide instantaneous friction measurements is providing essential databases to optimize hydraulic system design.

Mandate

Develop and manufacture a sensor assembly to measure friction in fluid mechanics. The assembly is equipped with a hydraulic loop which makes it possible to compare measurements made with three segment electro diffusion probes and a laser Doppler anemometer.

Development time

12 months

Technological advancements

- High-quality optical acrylic channel manufactured to extreme tolerances

- Optical facets on 4 sides of the main canal

- Removable window with zero lateral clearance to eliminate turbulence due to discontinuities in the inner surface of the canal

- Eliminates 100% of pump impulses at fluid contraction entry

- Universal module to allow evolution of the flow rectification system

Scientific advancements

Thanks to a triple wall probe, a method has been developed to capture the two instantaneous components of fluid friction on a wall. The method’s originality is that the device is non-intrusive, unlike most existing methods.

Specs

- Test bench dimensions: 13’L x 6′ x 12’H [4.0 m x 1.8 m x 3.7 m]

- Interior dimensions of main channel: 7’L x 5″ x 0.125″H [2.1 m x 125 mm x 3.2 mm]

- Main tank volume: 20 USGAL max. [80 L]

- Main channel inlet pressure: 5.0 psig max. [0.3 bar]