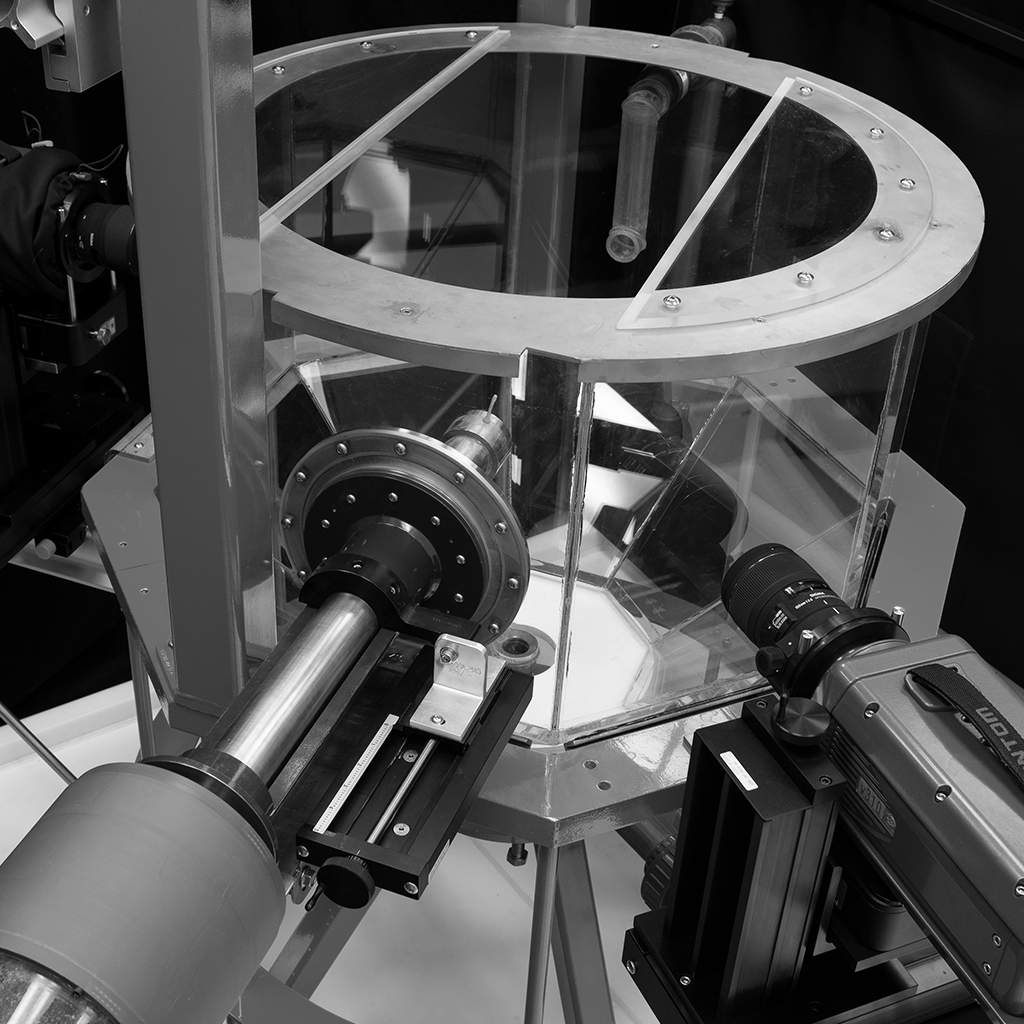

Test bench to study the instationary detachment generated by a jet with a PIV-3D system impacting a wall

Sector

Fluid Mechanics

Societal benefits

In the field of aeronautics, one of the main technological obstacles concerns the difficulty of predicting, and thus controlling, in real-time the flow around each part of the aircraft (nacelle, wings, engines and landing gear). This comes mainly due to poor knowledge of the mechanisms of boundary layer separation. This study shows that we are close to building a robust criterion to detect and control that phenomena, which has the potential to reduce fuel consumption and noise pollution.

Mandat

Develop and manufacture a test bench to perform 3D tomography measurements with a PIV (Particle Image Velocimetry) system. This system makes it possible to carry out fundamental and applied research in fluid dynamics and to study the phenomena of the unsteady boundary layer separation in the transient state, which occur in aeronautics and energy production.

Development time

5 months

Technological advancements

- Multifaceted basin of optical quality

- Support basin weight while maximizing optical access to all facets

- Injector with the possibility of inserting mechanical elements to correct the flow at the outlet

- Eliminates 100% of the pulses from the pump at the injector’s outlet

Scientific advancements

The measurements made it possible to obtain databases (speed fields) in order to validate a new boundary layer separation detection criterion. Non-wall fluid ejection phenomena have also been discovered and correctly predicted by the new theory.

Specs

- Optical quality basin with 16 facets

- 8 vertical facets and 8 facets inclined at 45° in the lower part of the basin

- Volume of the optical basin: 40 USGAL [150 L]

- Inlet diameter: 1250″ [32 mm]

- Injector travel range: 5″ [125 mm]

- PIV water and particle storage tank: 120 USGAL [450 L]

- Inlet pressure: 4.0 psig max. [0.3 bar]